Case Study: Downtime Fixed On Weigh Hopper

No Lost Production Since Installation

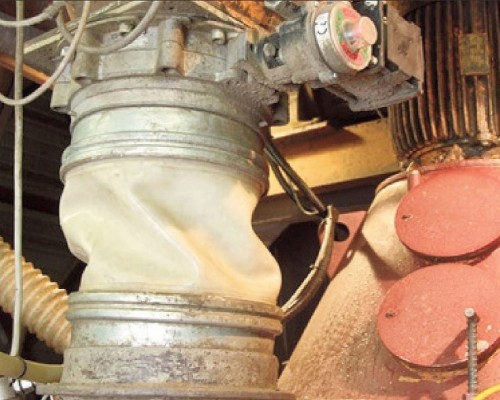

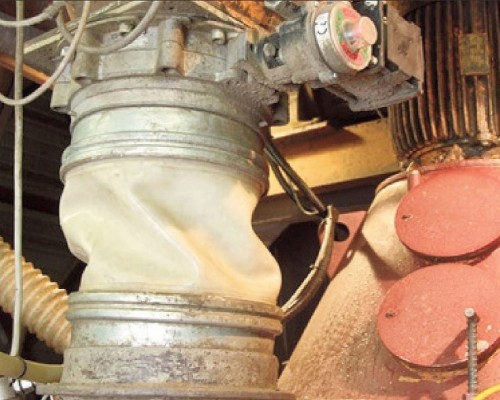

The canvas weigh hopper connectors at a leading British concrete products manufacturer absorbed moisture, making them prone to blockages.

This caused considerable lost productivity and poor weighing accuracy. To add to the problem, jubilee clips caused excessive dust leakage and made replacement extremely time consuming.

The Challenge

Major production issues with regular stoppages for blockages caused by the build-up of cement on the canvas connector due to moisture absorption.

There was leakage of dust around the connector fittings, and inaccuracy in the weighing due to the dust build-up. Regular intervention was required by maintenance staff to unblock and change the worn connectors.

Each change was extremely time-consuming due to the jubilee clip fastening system.

The BFM® Solution

By installing a polyurethane BFM® fitting, there is no longer an issue with down-time due to blockages and product is now free-flowing.

The general environment is much cleaner as there is no dust leakage from the connectors and weighing inaccuracy has been reduced.

The BFM® connectors are also outlasting their canvas predecessors by 10 times, and changing time for connectors is reduced from 20 minutes to 1 minute.

Benefits Achieved

Quick Changeovers

Quick Changeovers

Sleeve snaps into place for a perfect seal. Changing time for connectors now reduced from 20 minutes to 1 minute.

Reduced Downtime

Reduced Downtime

No more production loss due to connector blockages and connector changes.

Improved Hygiene

Improved Hygiene

Sealed system now stops dust leakage in the environment making the factory environment much cleaner.

Health & Safety

Health & Safety

The improved overall dust free environment makes the entire working area safer for staff.

Here's what the client said about BFM®:

“Our old canvas weigh hopper connectors used to block regularly which meant we had to stop production while we sorted it out. BFM® has totally solved the problem and we have had no lost production ever since. The factory is also much safer and cleaner”

- Factory Manager

Case Study courtesy of BFM® Distributor ProSpare (United Kingdom)