Preventing Electrostatic Hazards in Powder Processing

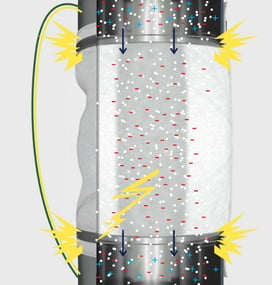

Spark discharges occur when two objects with different electrical potentials come close together. In a processing plant, this might happen when a charged, isolated piece of equipment—like a metal pipe—approaches another object, or even an operator, carrying a different electrical potential. The resulting spark can trigger dangerous fires or explosions.

This is why grounding every part of a bulk solids handling system is essential for safe operations.

Flexible Connectors: A Potential Risk Point

Flexible connections in bulk material lines are particularly susceptible to electrostatic buildup. As product moves through these non-conductive connectors, static charges accumulate on the material.

Flexible connections in bulk material lines are particularly susceptible to electrostatic buildup. As product moves through these non-conductive connectors, static charges accumulate on the material.

You might ask, “We have grounding cables on our equipment—doesn’t that solve the problem?”

Grounding cables are only effective if they complete the circuit across all transitions involving flexible connections, linking the top and bottom sections of piping. This ensures that no electrical potential difference develops that could lead to sparks or uncontrolled discharges.

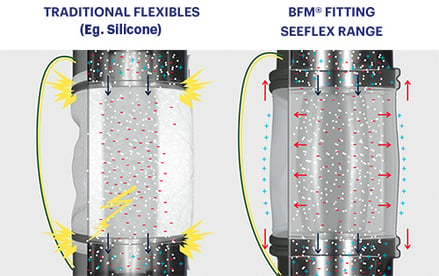

However, even with grounding in place, static charges can still accumulate inside flexible connectors. The constant movement of powder encourages the charge to seek the nearest conductive path—often the metal piping—potentially causing arcing or sparks within the connector itself before the charge safely reaches ground.

Selecting Safer Flexible Connectors

Manufacturers must comply with global safety standards, such as ATEX and IECEx, to minimize combustible dust risks. When choosing flexible connectors, both the design and material composition should be carefully evaluated.

While factors like product combustibility and flow rate are crucial, it’s always wise to opt for connectors made from static-dissipative materials. Keeping flexible connections as short as possible also reduces the surface area where static can accumulate.

What are static dissipative materials?

Static-dissipative materials typically have a surface resistivity between 1×10⁴ and 1×10¹² ohms. They help manage electrostatic buildup predictably, safely channeling the charge through grounded pipework.

Avoid insulative materials such as silicone or rubber, which do not dissipate static effectively and can pose serious safety risks.

BFM® Seeflex Connectors: Engineered for Safety

BFM® Seeflex connectors are crafted from a proprietary ether-based polyurethane designed to safely dissipate static. Popular models like the Seeflex 040E have a surface resistivity of 10¹⁰ ohms, while the specialist Seeflex 040AS achieves 10⁸ ohms.

These connectors are robust and, in transparent or semi-transparent versions, allow operators to monitor product flow. For applications where visibility isn’t critical, the Teflex NP Black, a pure PTFE connector, offers extreme chemical and temperature resistance with a surface resistivity of 10⁶ ohms—the most static-dissipative option in the BFM® range.

While no flexible connector can entirely eliminate static buildup, using static-dissipative solutions significantly reduces the likelihood of spark discharges and associated dust explosion risks.

Considering electrostatic hazards is just one part of overall plant safety, alongside explosion containment and preventing product leakage.

Contact us to find out how the BFM® fitting system can enhance safety in your plant by addressing electrostatic build-up and reducing the risk of combustible dust incidents.